68RFE Swap

General Info

I've been working with this swap since 2014 and since that time I have learned a lot about the 68RFE. I've ran it with fair success with lock up in 6th gear only using universal aftermarket transmission controllers that were or have been available but haven't been satisfied, especially shifting with the torque converter locked. There have also been many other functions I wanted but couldn't implement. This motivated me to develop my own aftermarket controller that I am now testing with, but until a solid testing time has been finished, and I am impressed with how it is meeting my very high expectations for it - sales for this swap are still paused. Check out a new you tube video here that I recently posted introducing the new system.

I currently have two customers that were running older systems using their trucks some, and for now they are all I need for "beta testers".

This swap is intended for trucks with stock or mild power upgrades, not for high horsepower. Aftermarket performance parts that have been in development for this trans for quite a while may change that, but still, it is really only intended for the owner that doesn't need big horsepower and won't ever buy a new truck. This type of owner likes the dependable 12 valve, or has a nice newer 5.9 but hates the 4 speed auto. If you are this kind of person and have a 5.9 Dodge Cummins pickup, that is the main reason why you might consider swapping in a 68RFE transmission. Even though it is similar to the lighter duty 5/45RFEs it was made for the 6.7 Cummins diesel with 6 pinion planetaries and no band type clutches are used. The gear ratios are awesome for a light duty Cummins work or play truck, having fairly high gearing but lower power.

Since you can use a factory style flex plate and adapter there are no worries about issues caused by flex plates that don't flex, buying and wiring up different starters, or parts not made to proper specs. Not having to buy expensive aftermarket adapter parts (12 valve engines do require a simple spacer), different transfer cases, or driveshaft services enables the swap to be done on a reasonable budget. The 68RFE is actually the same length as a 47 or 48RE, only the minimal difference in the factory adapter is the difference, so the stock driveshaft length works fine.

The mechanical shifter linkage for the transmission can even be used- I can provide a link to make it work. If your truck is a 97 and older 4-wheel drive, a '99 and newer floor mounted transfer case shifter is the best way to go so mounting the older style shifter is not an issue. The input gear for your current transfer case will need changed, unless you have a 5-speed manual now- but they are reasonable and not terribly difficult to change. '93 and older t-cases won't accept the different input, a Chevy 241 passenger side drop case may be an alternative.

On a side note- if you have come here looking for info on replacing a 68RFE with a 48RE, I can let you know that this requires a stand alone controller and custom valve body, so it is probably nearly as expensive as putting a Ford 4R100 in. I have to go on record for not recommending replacing a 68 with a 48. I have tuned a few of them for guys stuck with them and am not impressed with their performance. If you want something stronger consider a built Allison 6 speed, or a built 4R100 instead of the built stand alone 48RE.

Control System Info

More information will soon be coming in regard to the control system, but below is some general information that you may find interesting.

The price for the new control system

has not been finalized but will include a base calibration and tech support to get it installed,

and also fuse/relay box that provides all the relays and fuses for

reverse lights, neutral safety, and a few extra for other options.

The price will not include tuning, since

tuning requirements are quite variable depending on power and

vehicle use. Tuning support will be provided at

$50.00/hr, so plan to spend at least $50 on tuning and up to $350 or

more if you need precise tuning or a tow/haul calibration in

addition to a normal cal. If we figure on $250.00 for tuning that

should give you a close idea.

There will be some

diagnostic functions in my new system but beyond that you will have

to call me if you have problems, and I can help your local

transmission shop if needed. A Windows 7, 8.1 or 10 laptop computer

or tablet

is required to tune, diagnose, and change calibrations.

Controller Features

Fully adjustable Shift points/Lockups

Shift points are fully adjustable, and lockups can be enabled wherever you want them in 2nd through 6th. The control system unlocks the converter just enough during shifts just like a factory system so smooth shift quality and power transition to the next gear is maintained.

Exhaust Brakes

The 68 swap will work with an exhaust brake when the torque converter clutch is applied (locked up)- and I can tune the control module to lock the converter at zero throttle when the exhaust brake is activated - so yes it will work with an exhaust brake.

Tow/haul

The controller has a secondary calibration for towing or whatever different shift points you want. This can be used with a switch or even your current cancel od or tow/haul switch.

Manual Mode

Manual mode enables you to control the shifts completely and shift the transmission with a +/- switch.

Stand alone controller advantages:

- Relatively simple installation using standard analog signals from your engine, including throttle position sensor, RPM, and boost pressure for excellent line pressure control.

- Special features and programming to provide controls for specific applications, such as engine or transmission fan controls, different downshift points when the brake is applied in tow/haul mode, and etc.

- Full torque converter lockup in 2nd through 6th gear if desired- no partial lockup. Precise controlled slip controls for the converter that are custom tuneable for lock to lock shifts.

Stay "tuned" for more information to come.

Replace a 47RE with the 68RFE

The 47RE to 68RFE swap can make your 89-02 Dodge Cummins drive and haul like a new truck. Upgrading these older trucks is going to continue to be a serious consideration since the trend is to fix up an older truck that doesn't have all the emissions garbage to deal with. The 47RE is the worst part of these older trucks, infamous for poor shifting issues when cold, frequent band adjustments, overdrive problems, and an extremely high geared reverse.

To replace the 47RE with a 68RFE, my spacer is required (which enables the factory transmission adapter to be used), and the crankshaft pilot hole must be bored out with a tool that I have developed that can be used with your engine in the truck. It is also possible to use the 6.7 flex plate if desired, although the earlier flex plates can be used if a custom converter is built, or the center hole is bored out to allow the larger torque converter pilot to pass through.

The 6.7 adapter shouldn't be used on the 89-02 engines because two bolt holes are different that bolt the adapter to the engine. It's not possible to even re-drill one- and I wouldn't really recommend leaving those bolts out. Otherwise the 6.7 adapter does bolt on.

Durability Questions

Weaker than a 47RE?

There are some very loyal 47RE fans out there on the forums that like to say that the 47 or 48RE is the greatest trans that ever was and the 68RFE is a weak trans. Personally, I don't know why anyone besides racers that have a shed full of spare parts for them like the old school RE. The guys that are swapping out the 68 for a 48RE are those that have gobs of horsepower and will most likely break whatever is behind their engine sooner or later. These swaps require custom valve bodies and control systems as well, so it costs more than a guy thinks.

The 68 is a much better design and when compared

stock to stock is much stronger than the RE transmissions. It was built for the 6.7

Cummins making 350 hp

and 650 ft/lbs of torque, even up to 800 ft/lbs of torque starting

in 2011. So the stock 68RFE was at least built to handle

as much or more torque than a stock 48RE, and it does in the

thousands of 07-14 Dodge Cummins trucks on the road today. The

problems guys have had with it I believe are due mainly to stock

transmission tuning behind high performance engines. Sure you

can pay big bucks and get a 48RE built to handle more than a stock

68RFE, but it may make sense to put that money into a better trans

to begin with, especially if you are leaving your Cummins power

stock for good fuel economy and dependability. There are companies building performance upgrades for the 68RFE now,

and with the 6-speed Allison option available too it may be the time to leave the old 4 speeds behind

for your everyday work truck. If you are a racer, I would

recommend a Ford 4R100 over a 48RE any day.

Don't misunderstand, if you have a high performance Cummins

(over 400 hp) you are better off with an Allison - the 68RFE may handle 450 or higher but it's probably not be

worth the risk unless you just want to throw a cheap stock trans

behind your performance Cummins and take your chances. If you

are under the 400 hp mark the 68RFE is probably going to be just

fine, providing you take care of it and get it tuned well, just as

you would need to do with any transmission. I promise you will

like the gear ratios. That's my two cents, take it or leave

it. If you still don't agree, it's ok with me-

keep your 4 speed and it's sluggy reverse☺. Shifting to

4 low if you have it does help a ton when backing up a heavy trailer.

All the

teasing behind, I do realize a swap is expensive, rebuilt

transmissions are expensive- and new trucks are very expensive.

All any of us are trying to do is make a living and hopefully have

just a little fun and less stress doing it. Many of us depend

on our trucks every day to earn a few dollars, and they need to be

the best they can be.

Late model vs Early model

The later model 68RFE transmissions (part numbers under the bar code ending in "AE" or "AF" on the sticker, or the same last characters on the stamped code just under it on the case) got some upgrades to the valve body - so these are the best transmissions to purchase for a swap. As far as I know the only difference to the '11 and newer model that handles 800 ft/lbs is the converter and the factory tuning.

Case Cracks

One more durability question to address is case cracking. There have been more than a few instances of this happening, and the general consensus is that it is caused by bad vibrations due to bad u-joints, worn extension housing bushings (the bushing that supports the slip yoke of the rear driveshaft) or bent or unbalanced driveshafts. It may help to install an aftermarket aluminum oil pan and definitely don't ignore any bad vibes. It is worth pointing out that the 47/48RE has also been known to crack as well and Allisons too. Even 5R110s have had case problems. Now in all fairness, if the case cracks on one of these transmissions it probably is currently cheaper to repair than a 68- but the point I'm making is all of them have potential to crack if subjected to the wrong stress.

Lock to Lock shift slippage

Locking the torque converter in lower gears and shifting to the next gear locked can help get more power transfer to the ground where you need it. This type of transmission tuning is commonly desired, especially when there is a monster under the hood- and the 68RFE especially shines with lock to lock shifts due to the close ratio gaps. There are valid concerns however, that doing this with the 68 can cause clutch slippage. This was proven to be true with my first high performance customer using my old control system. He was using a 68 with clutch and pressure upgrades, basically everything available except for the M3GA drum- and did have some 4-5 and 5-6 lock to lock slippage issues, initially at least likely due to the shock of the shift.

This problem of lock to lock slip and the other side of the fence - damage to input shafts, drums, and converter hubs - led me to develop the TCS module, a helper module that was used alongside the control module I used previously. This extra module gave me more controls to unlock the converter just enough in a very precise way according to load during the shift. When this was adjusted properly, it made lock to lock shifts as smooth as a normal shift. This controlled slip has to be very precise, too much slip and the converter clutch could be damaged or shift quality will suffer, not enough slip and the shift is too shocking to the system without employing a slow slushy shift. This programming transfers over to my new, single controller system.

See my transmission swap comparisons page for more info on other transmissions and how they stack up to each other.

68RFE Swap Parts and Tools

- Stand alone 68RFE controller: Price yet to be determined Included in this basic price is the controller, harness, USB cable, a base calibration, and tech support to get it installed. This price does not include tuning. Tuning support is provided at $40.00/hr. Plan to spend at least $40 on tuning and up to $350 or more if you need a tow/haul calibration in addition to a normal cal.

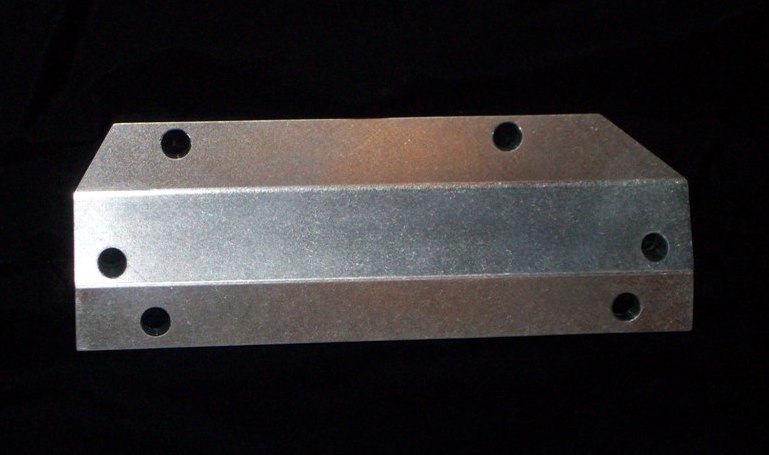

- 89-06 Cummins adapter spacer: $250.00 This spacer is required to use your original adapter plate with the 68RFE. The inner and outer profile match the transmission even better than the OEM 6.7 adapter. It is CNC machined out of aircraft quality aluminum and includes longer dowel sleeves and bolts.

- Cummins crank pilot boring fixture: This fixture bolts to the adapter plate as the transmission would and is used to bore the crank pilot to the correct size, allowing the 68RFE torque converter to be used as is. '06 and newer Dodge Cummins engines should not need any modification. See a you tube video of it in action here.

- Trans mount adapter: $100.00 If you have a '94-'02 Dodge, the trans mount adapter allows you to bolt your transmission mount to the 68RFE transmission and use your original cross member.

- Transfer Case Input Gear: The output shaft of the 68RFE is 29 spline. To use your current transfer case you may have to replace a 23 spline input gear for the 29. Price and availability depends on your specific application and the quality of shaft you desire.

- Shifter Linkage: I provide instructions to connect your original shifter linkage to the 68RFE, the stock shifter linkage for 94-98 trucks will work!